Marine environments are inherently challenging, with ships often operating in areas where flammable gases, vapors, or combustible dust can create hazardous conditions. Marine Explosion Proof Light Symbol are critical for ensuring safety in these environments, but understanding the symbols and markings on these products can be daunting for buyers. This guide aims to demystify these symbols, empowering you to make informed decisions when selecting marine explosion-proof lights that meet your specific needs.

Basics of Marine Explosion Proof Light Symbol

What Are Explosion-Proof Light Symbols?

Explosion-proof light symbols are standardized markings that communicate a product’s suitability and performance in hazardous environments. These symbols are governed by international standards such as IECEx (International Electrotechnical Commission System for Certification) and ATEX (Atmospheres Explosibles), ensuring global consistency and reliability.

Why Are These Symbols Important?

- Safety Assurance: These symbols confirm that the light fixtures are designed to prevent ignition in potentially explosive environments.

- Compliance: They ensure the product meets regulatory requirements for specific regions or industries.

- Efficiency: By understanding these symbols, buyers can quickly identify products that match their operational needs, avoiding costly mistakes.

Common Explosion-Proof Light Symbols Explained

Area Classification (Zone or Class/Division)

Hazardous areas are classified based on the likelihood and frequency of explosive atmospheres:

- Zone System (International Standards like IECEx, ATEX):

- Zone 0: Explosive gas is continuously present (e.g., inside oil tanker storage tanks).

- Zone 1: Explosive gas is likely to occur during normal operations (e.g., near fueling stations).

- Zone 2: Explosive gas occurs only under abnormal conditions (e.g., poorly ventilated engine rooms).

- Class/Division System (North American Standards like NEC):

- Class I, Division 1: Flammable gases or vapors are continuously present.

- Class II, Division 2: Combustible dust occasionally exists.

Pro Tip: When choosing lights for marine environments, consider the specific zones onboard your vessel. For example, oil tankers often require Zone 0-rated lights for storage areas due to constant exposure to explosive gases.

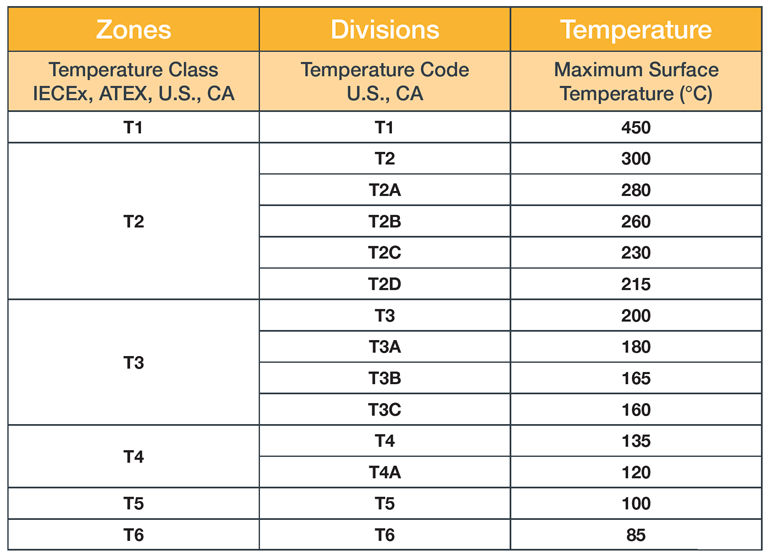

Temperature Rating (T-Class)

Temperature ratings indicate the maximum surface temperature of a light fixture relative to the ignition temperature of surrounding substances:

- T1 (450°C or higher): Suitable for substances with high ignition temperatures.

- T6 (85°C or lower): Ideal for environments with low ignition temperatures.

Example: In a ship’s engine room, where flammable gases may have lower ignition points, T6-rated lights are essential to prevent accidental ignition.

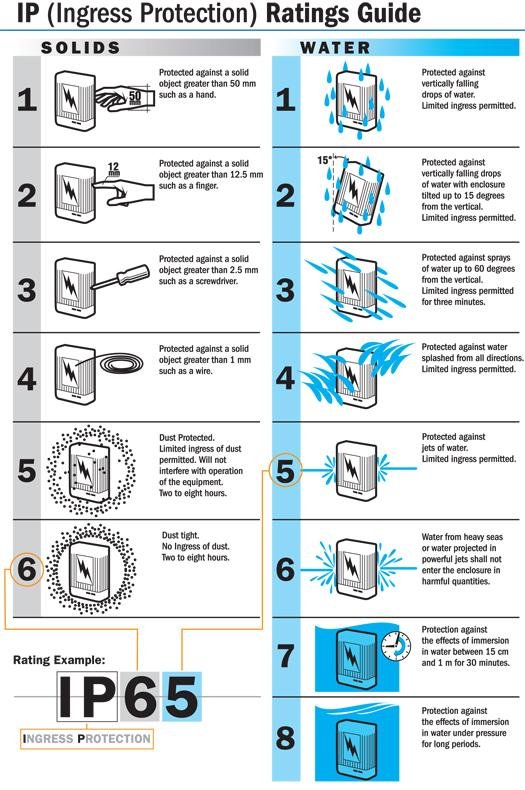

IP Rating (Ingress Protection)

IP ratings define a product’s resistance to solid particles and liquids:

- IP66: Completely dust-tight and resistant to strong water jets.

- IP67: Dust-tight and capable of temporary immersion in water.

Why It Matters: Marine environments expose lights to salt spray, humidity, and occasional splashes. IP66 or IP67 ratings ensure durability and reliability under these conditions.

Certification Marks

Certification marks validate a product’s compliance with safety standards:

- IECEx: Recognized globally for hazardous locations.

- ATEX: Required for European markets.

- UL: Commonly used in North America.

Tip for Buyers: Always check certification marks before purchasing explosion-proof lights to ensure they meet your region’s requirements.

Special Requirements for Marine Explosion-Proof Lights

Marine environments impose unique demands on explosion-proof lights due to their harsh conditions:

- Corrosion Resistance:

Salt spray and humidity can corrode standard materials quickly. Opt for fixtures made from stainless steel or aluminum alloy to ensure longevity. - Shock Resistance:

Ships experience constant vibrations during operation. Explosion-proof lights are designed with anti-shock structures to maintain stability and prevent damage. - Energy Efficiency:

LED technology is increasingly favored for marine applications due to its high efficiency, long lifespan, and reduced maintenance costs.

Case Study: A fishing vessel operating in humid tropical waters found that switching to LED-based explosion-proof lights with IP67 ratings reduced energy consumption by 30% while improving reliability in harsh conditions.

How to Choose the Right Product Based on Symbols

Case Studies

- Oil tanker storage tanks require Zone 0, T6-rated explosion-proof lights with IP67 protection to handle humid conditions and continuous exposure to explosive gases.

- Fishing vessel decks may need Zone 2, T4-rated lights with shock-resistant features due to occasional exposure to flammable substances during fueling operations.

Buying Tips

- Identify hazardous area classifications onboard your vessel.

- Verify certifications such as ATEX or IECEx based on your region.

- Match technical specifications—such as light efficacy, power output, and material composition—to your operational needs.

FAQ

Q: How can I quickly determine if a light is suitable for a hazardous environment?

A: Check certification marks like ATEX Zone 1 or IECEx Zone 2 on the product label. These indicate compliance with safety standards for specific zones.

Q: What if a light doesn’t have clear markings?

A: Contact the supplier directly for technical documentation or request third-party testing results to verify compliance.

Understanding marine explosion-proof light symbols not only helps buyers select compliant and safe products but also improves purchasing efficiency while minimizing risks. When buying such lights, focus on area classification, temperature rating, protection level, and certification marks while tailoring choices to specific application scenarios.